PTO clutches

The PTO clutch is a key element in agricultural machinery, enabling the transfer of power from the tractor engine to a variety of external devices, such as mowers, spreaders, or sprayers. The PTO clutch acts as an intermediary, allowing for safe and efficient connection and disconnection of the drive, protecting both the tractor and the machines working with it from overloads and damage. Depending on the needs, PTO clutches can be manual or automatic, and their selection is key to ensuring optimal operation of the entire system.

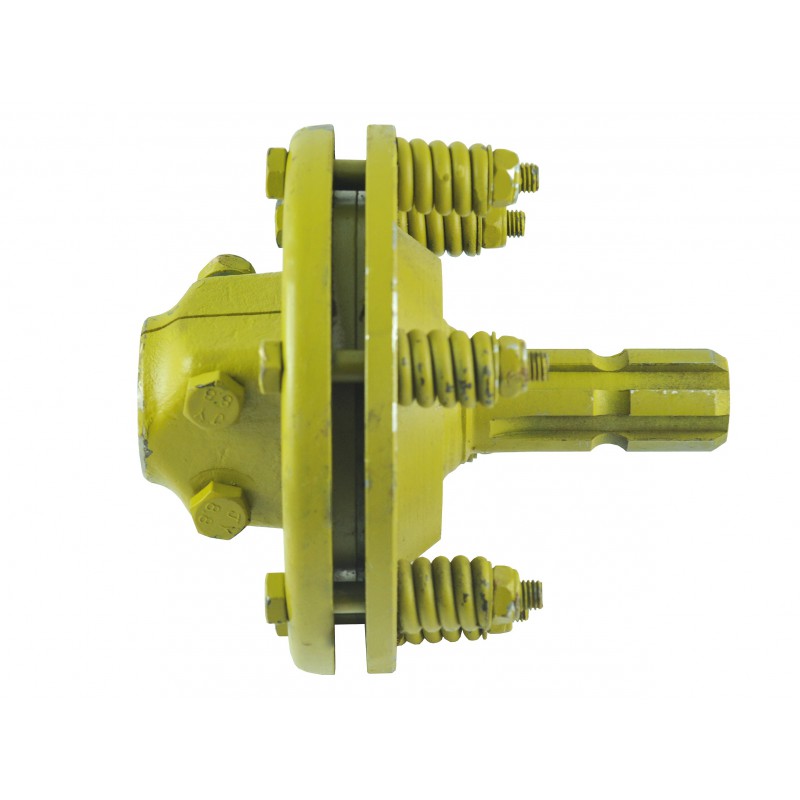

A friction clutch is a type of mechanical clutch that uses friction between contact elements to transfer torque. It is commonly used in various machines and vehicles, including agricultural machinery, where it often acts as a PTO clutch. A friction clutch consists of plates that are pressed together, allowing power to be transferred from one shaft to another. When the pressure is reduced or removed, the plates are free to rotate, allowing the drive to be disengaged. Friction clutches are valued for their simplicity, reliability, and ability to smoothly engage and disengage drive, making them a key component in many mechanical systems.

The PTO directional clutch is a specialized device used in agricultural machinery that allows power to be transferred in only one direction of rotation. This is important in the context of providing protection against mechanical damage that may occur if the drive shaft rotates in the opposite direction. The directional clutch works on the principle of a ratchet mechanism or a one-way bearing that blocks the shaft from rotating in the wrong direction, while allowing it to rotate freely in the desired direction. The use of a PTO directional clutch is crucial in machines that require precise control of the direction of rotation, such as some types of balers, seeders, or shredders. Thanks to this component, these machines can operate more efficiently and safely, minimizing the risk of failure or damage resulting from uncontrolled shaft rotation.