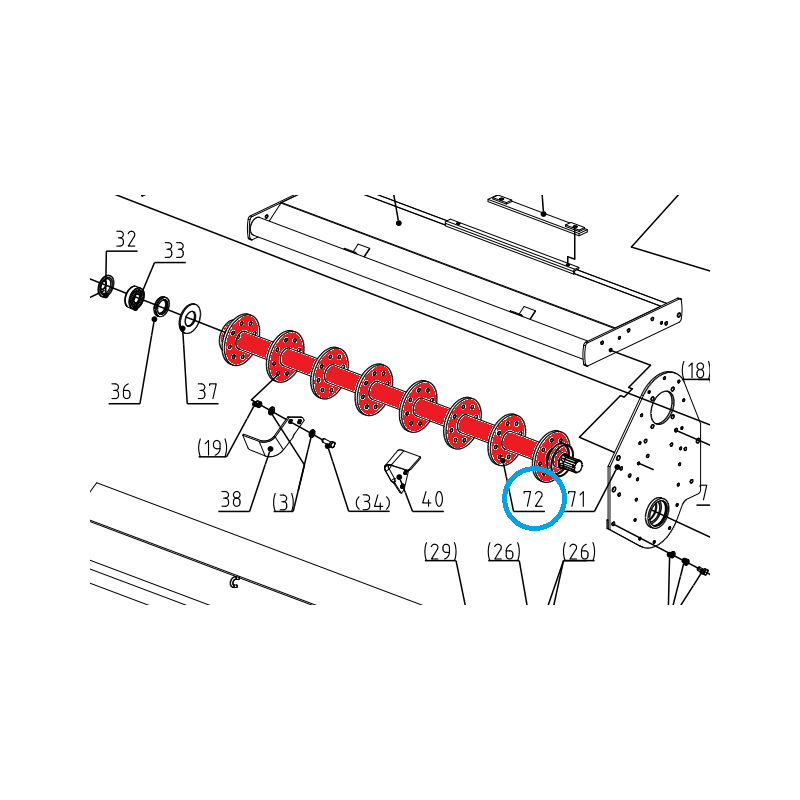

Rollers

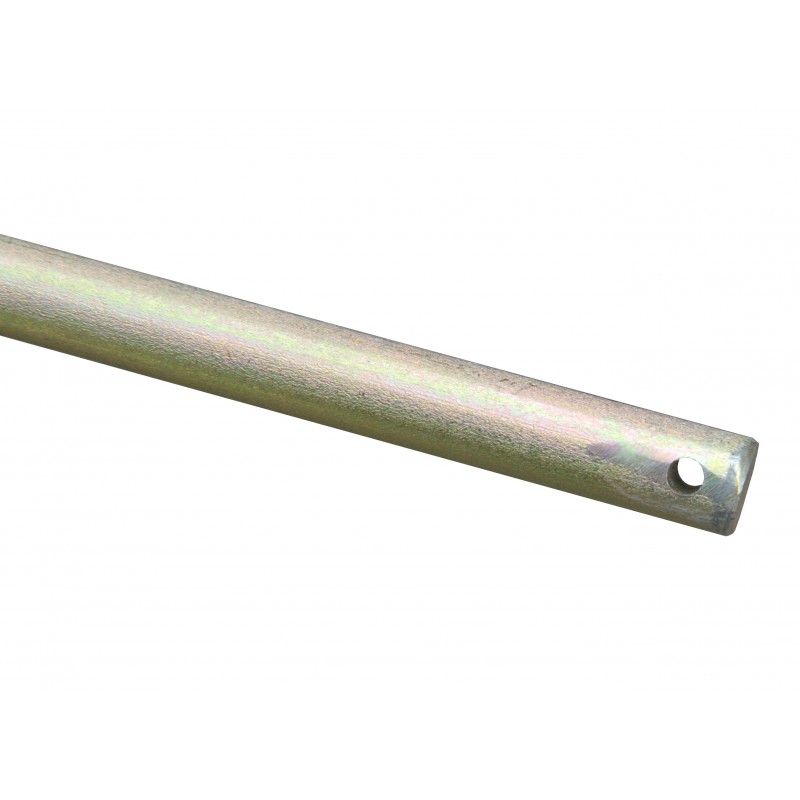

String roller

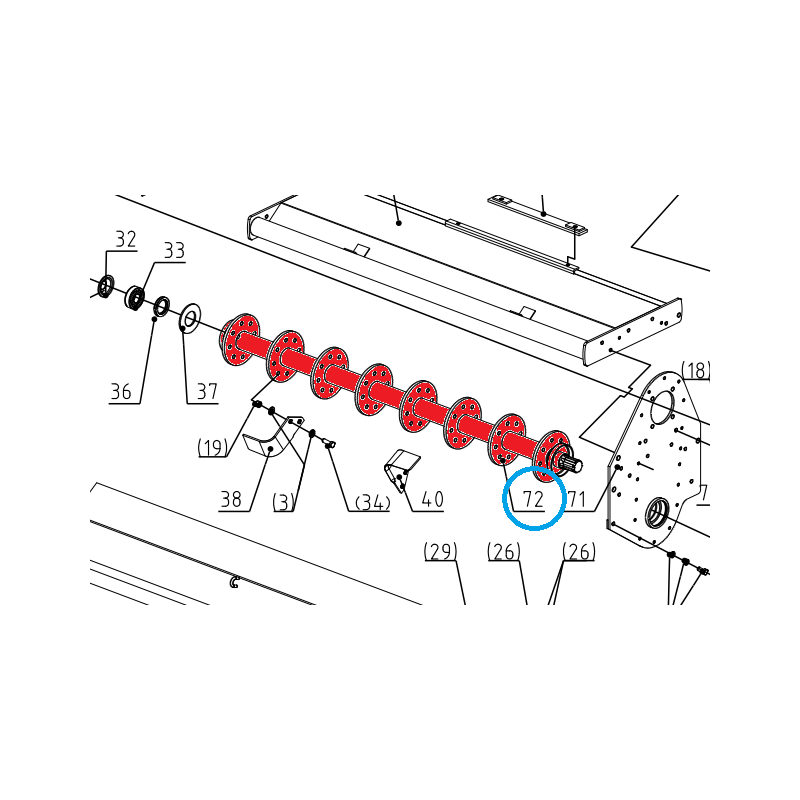

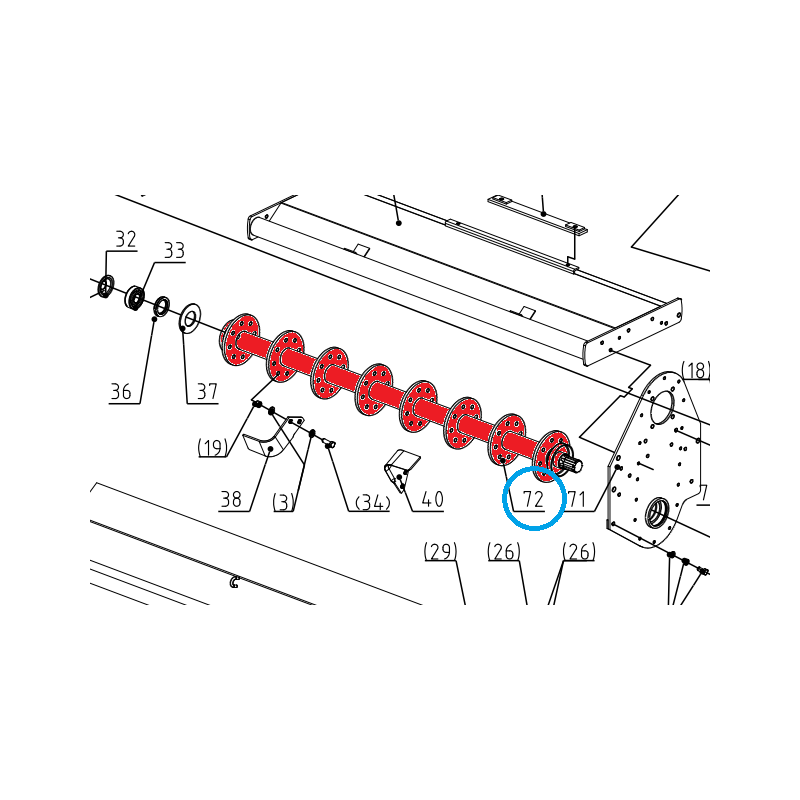

The string roller, also known as the separation roller, is a specific type of roller used in separation tillers. It consists of a series of strings (rods) mounted along the main shaft. These rods are responsible for turning and sifting the soil, which allows stones, roots and other large debris to be separated from the cultivated soil.

Features and advantages of string roller:

Separation: The string roller effectively separates stones, roots and other large particles from the soil. This results in well-prepared soil for sowing or planting.

Loosening: In addition to separation, the string roller also loosens the soil, which improves its structure and air and water permeability.

Screening: Due to its design, the string roller acts as a sifter, allowing finer soil particles to pass between the bars while larger contaminants remain on the surface.

Key technical aspects:

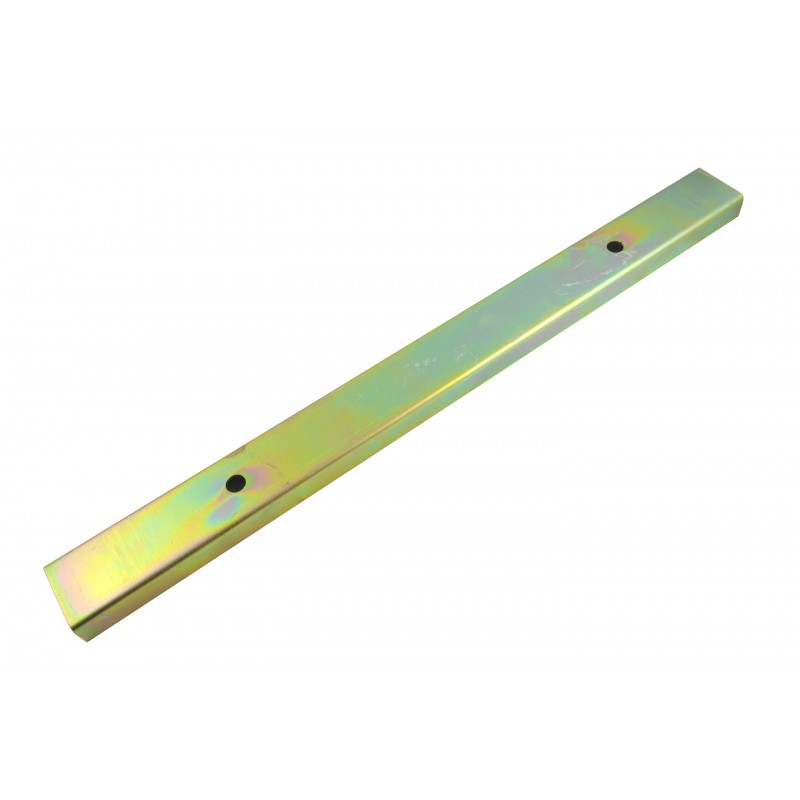

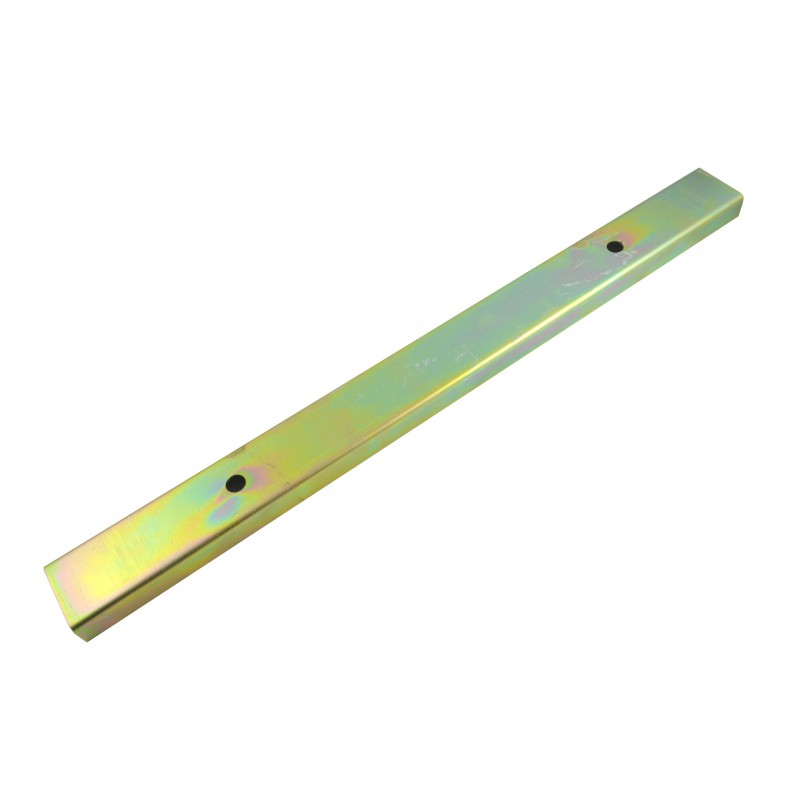

Materials: Shaft strings are typically made of high-quality steel that is resistant to wear and corrosion.

Construction: The strings are mounted on the main shaft at regular intervals. The shaft may have different lengths and diameters, depending on the tiller model and its purpose.

Drive: The string roller is driven by the tiller engine, just like the standard main shaft. It can be directly connected to the transmission or driven via V-belts.

Adjustment: Some tiller models allow the string roller to be adjusted to adjust the depth and intensity of loosening and separation to soil conditions.

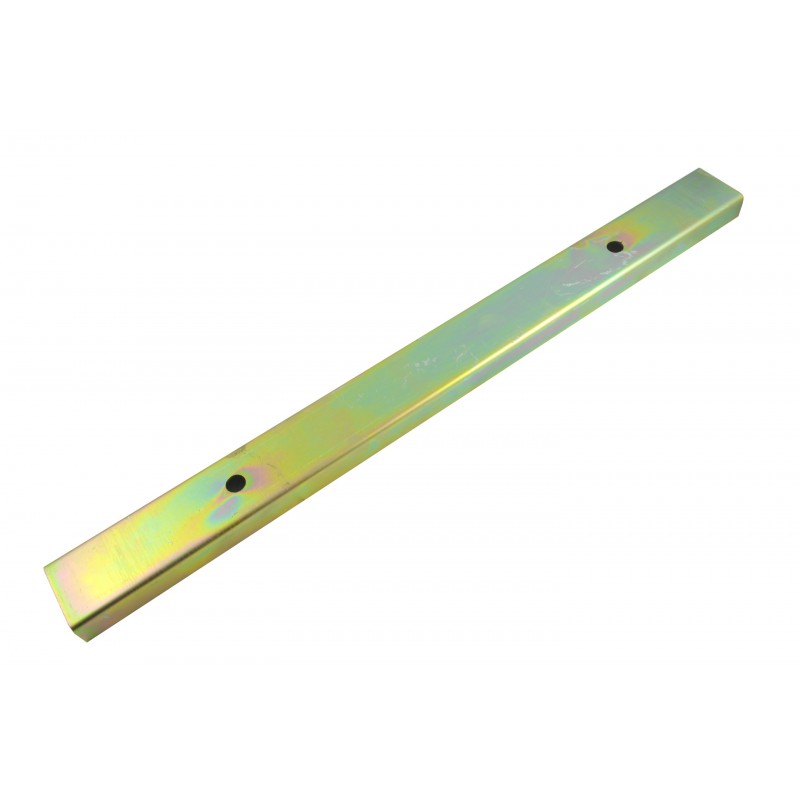

Main shaft of the tiller

Functions:

- Power Transmission: The main shaft transfers the power generated by the engine to the blades, allowing them to rotate and work in the soil.

- Knife support: Knives are mounted on the main shaft, which loosen and mix the soil.

Construction:

- Materials: The main shaft is usually made of high-quality steel, which ensures its strength and resistance to heavy loads and corrosion.

- Shape and size: The dimensions of the main shaft may vary depending on the tiller model. The shaft can have different diameters and lengths, adapted to the specific needs of the device.

- Bearings: The shaft is mounted in bearings that ensure smooth rotation. Good bearings reduce friction and wear of components.

Knife mounting:

- Mounting types: The knives can be attached to the main shaft in various ways, e.g. using screws, pins or special clamps.

- Arrangement of knives: The knives are evenly distributed along the roller, which ensures even loosening of the soil.

Application:

The main shaft is used in various types of tillers, including manual models powered by combustion engines and electric ones. This is a key element in devices intended for both small home gardens and large farms.