Condition

New

Minimum required tractor power (HP HP PS)

10

Number of knives (pcs)

4

Trailer hitch

Yes

Weight (kg)

130

R80 roller chipper (4 knives) Remet CNC Technology

Do you have any questions?

Tractor chipper - how does it work?

These are devices that, as the name suggests, are designed to be used in conjunction with agricultural tractors . A tractor chipper works by connecting to the PTO shaft, which is why individual chippers require connection to a tractor with the appropriate engine power. Wood shredding machines are commonly used in forestry and agriculture. Their use allows for quick, precise and safe processing of even a significant number of trunks and branches.

Basic types of chippers: disc and roller. What are the differences?

In disc chippers, the element that shreds wood is a metal disc/disc with mounted blades (knives). This solution was patented in 1922 by German inventor Heinrich Wigger. The rotating disc/disc is set perpendicularly to the wood fed into the machine (manually or by means of a conveyor belt). The rotating disc with knives shreds it into chips (shavings), which are then thrown out of the device through the discharge chute. By choosing a disc chipper , we obtain fine material of uniform shape and size, which can then be used for mulching, for fuel, for the production of chipboard.

Roller chippers are machines designed to quickly process branches or tree trunks into short pieces. These devices are great for forests, parks, orchards or farms. Roller chippers have a completely different shredding mechanism. It is a rotating cylinder with sharp protrusions (knives). The material we get is wood cut into pieces about 10-16 cm long.

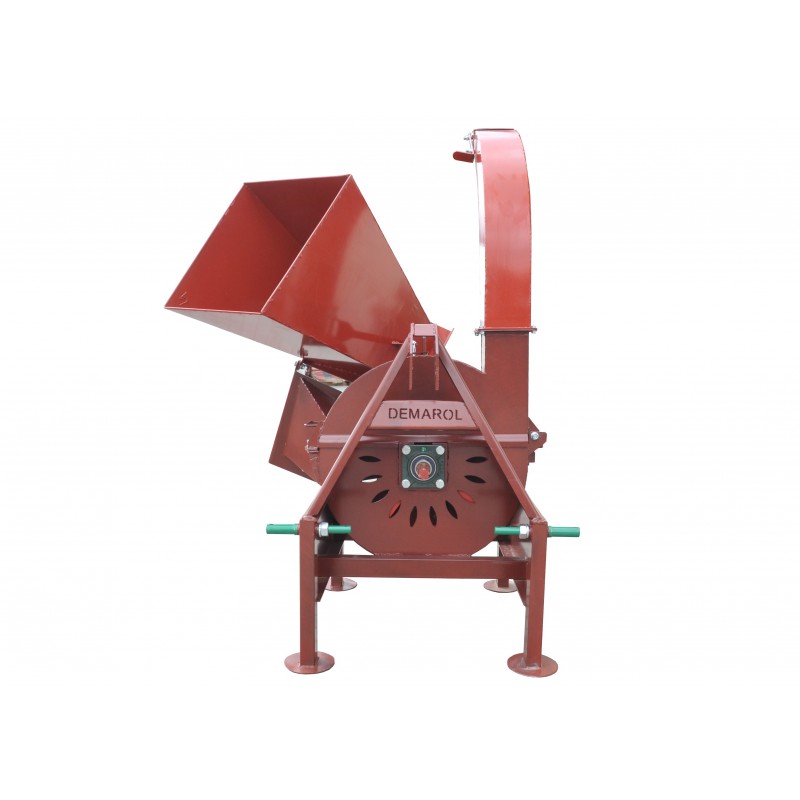

The R-80 roller chipper is designed for cutting branches with a diameter of up to 7 cm (fresh soft wood).

The construction of the chipper is welded, fully disassemblable, ensuring the appropriate rigidity and durability of the machine. The cutting mechanism has been precisely made, ensuring the appropriate quality, accuracy and concentricity. This translates into a long service life of the components and the entire device.

The chipper mechanism is equipped with a clamping and expanding sleeve that is used to position the cutting knives, it also serves as an overload protection. The chipper can be additionally equipped with a flywheel/belt and a foldable belt conveyor. The belt allows for discharge along or to the side of the device.

R80 roller chipper - machine equipment:

- rear shaft for flywheel/belt pulley,

- adjustable clearance between knives,

- induction hardened gears,

- long foldable feed hopper,

- ball hitch for trailer, towing capacity 1000 kg,

- outlet type: straight - without bagger,

- max. branch cutting diameter (fresh soft wood) 70 mm,

- max. branch cutting diameter (fresh hardwood) 60 mm,

- max. branch cutting diameter (dry hardwood) 50 mm,

- length of cut branches 9 - 15 cm,

- production of cutting knives made of HARDOX type 500 steel,

- feed hopper 62/38 cm.

It is possible to equip the chipper with:

- single or double bagger,

- 2x17 mm,

Specification

REMET CNC TECHNOLOGY has been operating on the market of precision metal processing and machine production since 1998.

It is a modern Polish company specializing in machining and production of precise metal components using advanced CNC (Computer Numerical Control) technologies. Thanks to its experience and modern machinery,

Remet CNC Technology has gained recognition as a reliable supplier in industries such as aviation, automotive, defense and medicine.

Many years of experience have allowed us to properly recognize the market and customer needs in the field of wood processing.

Remet CNC Technology constantly invests in the latest machining technologies and process automation to maintain a high level of quality and production efficiency. The company uses advanced CAD/CAM systems in the design process and state-of-the-art CNC machining centers that enable the implementation of even the most complex tasks.